Who We Are

At My Oil Doctor, we are a team of dedicated professionals who are passionate about providing top-quality oil products and services to our customers. Our goal is to ensure that every customer receives the best possible care and attention when it comes to their oil needs.

With years of experience in the industry, we pride ourselves on our knowledge and expertise in all things oil-related. Whether you need a simple oil change or a more complex service, you can trust that we have the skills and resources to get the job done right. When you choose My Oil Doctor, you can rest assured that you are in good hands.

Our Mission Statement

Because Failure is not an Option

Our mission is simple to offer user-friendly on road analysis solutions to everybody.

We are committed to integrity, excellence, and continuous improvement, ensuring that our customers can streamline their operations and achieve their goals. Our unique approach involves leveraging cutting-edge technology and fostering a culture of creativity and collaboration, allowing us to deliver unparalleled value and support.

John Lakey

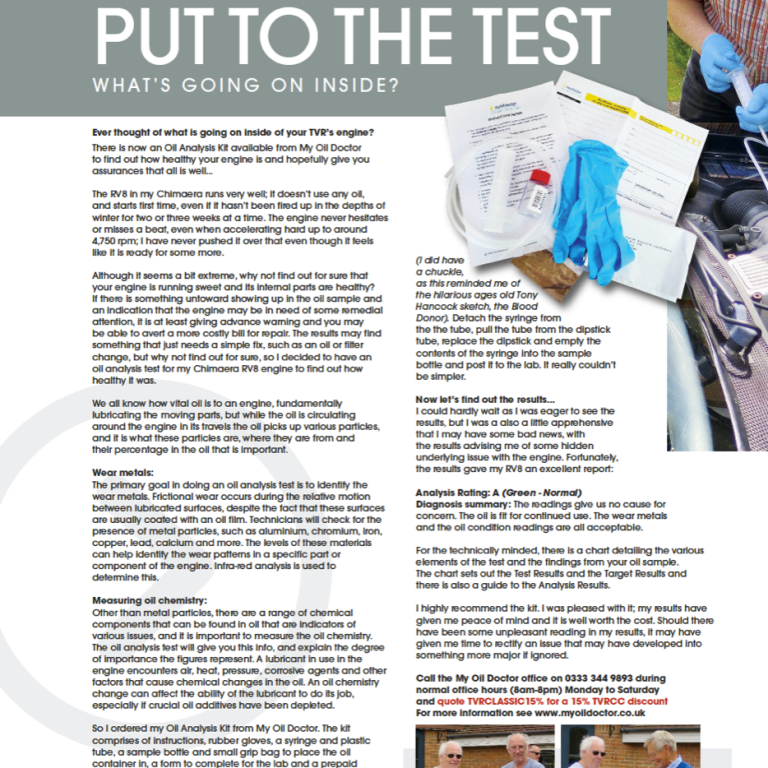

We met John at Tatton Park Classic Car show on our stand. He loved the concept and we agreed to do some articles with Classic Car weekly.

John Lakey

John used our sample kits on his MG and used the results and feedback from the lab to write the above article.

TVR Owners Club

We have many TVR customers who use our service on a regular basis, and have built a TREND story about their cars engine and performance.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.